Gear couplings

Get a quote

+39 02 939 6831

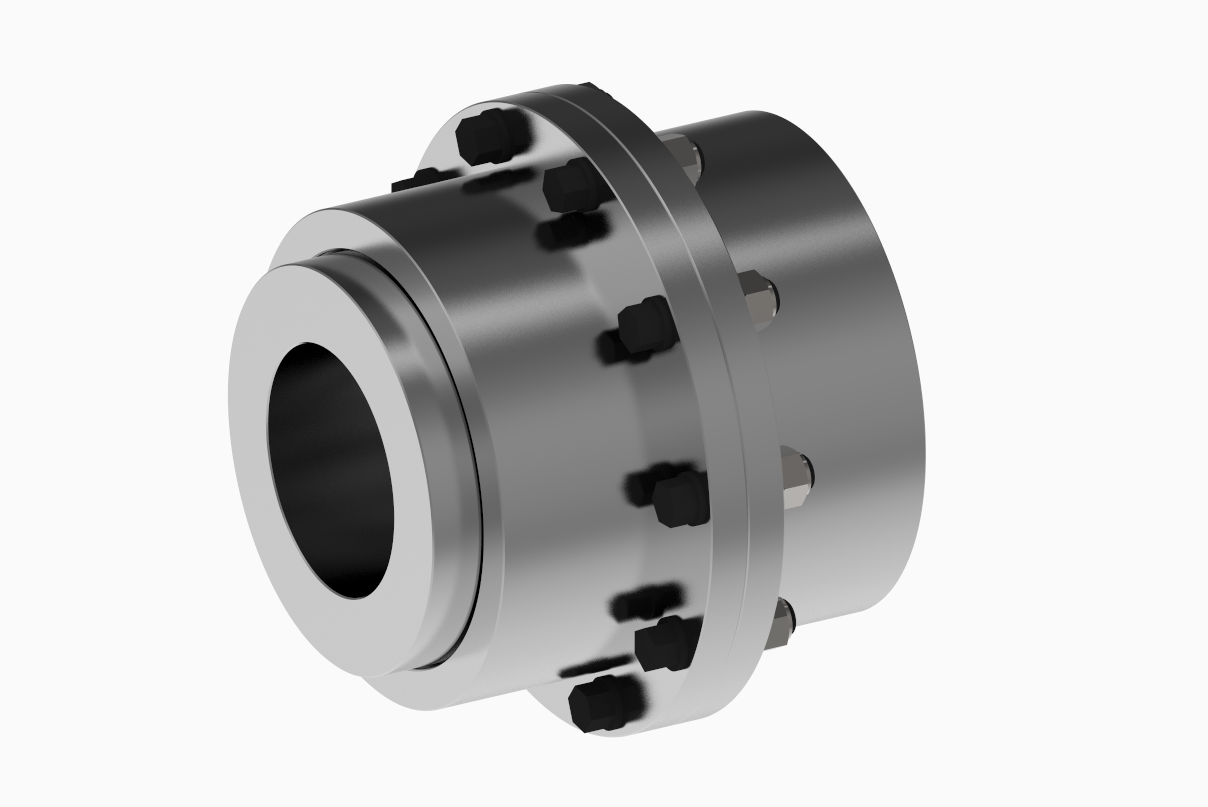

Gear couplings

The gear coupling is a motion transmission device designed to connect two rotating shafts to transmit torque in a torsionally rigid manner and compensate for angular, parallel and axial offsets. The gear coupling also has the characteristic of not transmitting axial thrusts.

The gear couplings are made up of:

- A hub for the crankshaft with domed external teeth;

- A hub for the motor shaft with domed external teeth;

- Two flanged sleeves, both with internal teeth, joined with calibrated screws;

- holding gaskets seals on both sides and grease nipple.

The elements that make up the coupling are made of alloy steel which for specific demanding applications, undergo surface heat treatment to have greater wear resistance.

The calibrated screws are made of high-strength steel with a grinding shank to prevent oxidation or seizing and, thus, facilitate disassembly, a phosphating surface treatment can be performed.

The crowned involute hubs' gearing, made with minimal backlash between teeth, mainly allows angular misalignment of up to 1°.

Grease lubrication is provided through grease nipples located on the coupling flanges of the sleeves. Sealing rings ensure holding gaskets provided the temperature does not exceed the prescribed operating temperatures of -20 to +80C.

Do you need to make a mechanical transmission of motion?

Our engineering department is at your disposal for the design and manufacture of power transmission couplings.