Services

Get a quote

+39 02 939 6831

Overhaul, Maintenance, Revamping, Special Products

Mechanical engineering professionals at your service

SAPITFLEX, also through its sister company SAPITFLEX Engineering, provides on-site services and assistance to customers. SAPITFLEX is active in the area of complete mechanical plant services/systems, ranging from the overhaul of specific equipment to the supply of mechanical or system components to replace existing ones, to the revamping of machines or plant parts.

Revamping is the renovation and refurbishment of complex industrial plants in order to extend their life cycle within the production process and restore obsolete technological processes by replacing them with modern technologies.

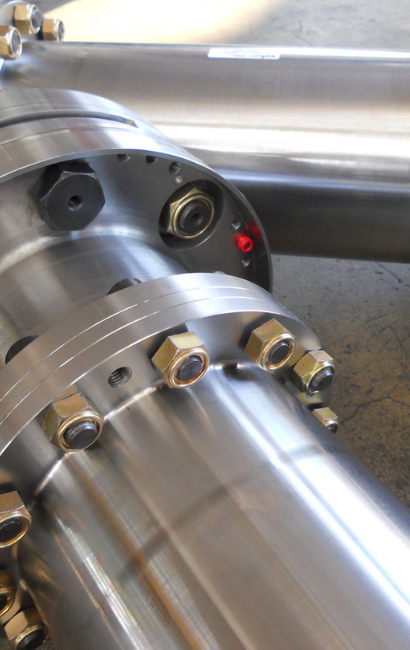

Revamping is an overhaul and rebalancing of hydraulic coupling to restore the coupling to its original condition of functionality and durability.

The process of reverse engineering is the detailed analysis of the operation, design and development of an object in order to produce a new application that has a similar operation, perhaps improving or increasing the efficiency of the same.

Gears are mechanisms that enable the operation of all mechanical devices by transferring motion from one machine element to another. Thus, gears have the ability to activate the parts of a machine in a consequential and controlled manner by increasing their strength and decreasing their wear and tear.

Laser shaft alignment is the most efficient way to align machine shafts because it saves time and money: higher machine availability, longer service life and maintenance intervals, and lower power consumption.

This operation restores the rotating components to their original degree of balance.

Parts are manufactured from drawings, from worn or broken samples, or from customer specifications with the cooperation of our technical department. The mechanical part is analyzed in the context in which it is to work, a hardness test is carried out and the type of material that will undergo machining such as turning, milling, drilling, grinding and heat or surface treatments is chosen.

Design, rebuilding and overhaul of complete cardan shafts

- Components status check (forks, pins and transverse bearings, groove profiles) also with NDT (non destructive testing)

- Survey and reverse engineering for components to be rebuilt with a design different from Sapitflex standards.

- Design verification of components with shearage or abnormal wear and redesign.

- Drawings of all components to be rebuilt.

- Recovery of components to be reused.

- Replacement of commercial components (rollers, bearings, seals, screws, etc.).

- Reassembly, painting and functional testing.

Various mechanical constructions and revamping of plants

- Revamping of the robotic welding system.

- Construction of the SL10GX precision rotary lift interconnected with the robot.

- Revamping and retrofitting of machine tools.

- Overhaul of hydraulic couplings.

- Overhaul of blast furnace gas purification system.

Overhaul of pumps and valves

- Overhaul of all brands of gate, disc, retaining, ball valves and testing according to standards with internal certificate.

- Replacement of gaskets: performed using seals suitable for the product.

- Replacement of damaged or worn components with original spare parts.

- Application of electric, pneumatic, hydraulic actuators to all types of valves.

- Overhaul of single-stage and multi-stage centrifugal, positive displacement, gear, vertical submersible, dispensing, liquid ring vacuum, vacuum, piston, diaphragm pumps.

- Special tests: certified tests are carried out, RT industrial radiography, UT defect and thickness ultrasounds, ET eddy currents, LT helium leak tests, MT magnetoscopy, PT liquid penetrants, PMI chemical analysis of materials in the field, IT thermographic inspections.

Component construction

- Shaft inspection, metallisation, adjustment, balancing.

- Checking and replacing main and thrust bearings.

- Replacement of carbon seal rings.

- Overhaul of speed control system, check of adjustment masses and possible replacement.

- Overhaul of the steam inlet control box.

- Overhaul of hydraulic or mechanical servomechanisms.

- Reverse engineering and rebuilding of components.

- Overhaul of turbine gearboxes/multipliers, alternator, gear design and rebuilding.

- Design and construction of mechanical transmission couplings.

Design, construction and overhaul of complete special gears and gearboxes

- Design skills for the dimensioning and diagnostic verification of all the mechanical components of a gearbox and in particular the various types of gears;

- Systematic processing of the reverse engineering activity, allowing design tools to be available at all times for current and future interventions on the same machine;

- Internal and outsourced availability of the best specialised skills and production means for the construction of components, with particular reference to specific types of gears;

- Precision mechanical assembly and installation with particular reference to the mechanical parts of kinematic chains and accessories (gears, shafts, bearings, non-return devices, lubrication systems).

All these interventions serve to:

- Obtain from a reconditioned machine performance and durability comparable to that of a new machine;

- Contain overhaul costs by adopting suitable solutions for the recovery and reuse of damaged components (for example, it is almost always possible to reuse wheels with non-worn gear or rotating them 180° to make the non-functioning side of the gear work, or the gearing of the wheel and the rebuilding of the pinion with an increase so as to recover the correct clearance between the gear coupling profiles).

Design, reconstruction and overhaul of complete gimbal spacer

- Component condition check (forks, pins and bearings crosses, spline profiles) also with CND;

- Surveying and reverse engineering for components to be rebuilt of designs other than Sapitflex standards;

- Design verification of components with cracks or abnormal wear and tear and their redesign;

- Drawing construction of all components to be rebuilt;

- Restoration of components for reuse;

- Replacement of components from trade (rollers, bearings, seals, hardware, etc.);

- Reassembly, painting and functional testing.

Areas of intervention

The work methodology, oriented towards proposing solutions designed to meet specific customer requirements, combined with the high quality level of the products offered, have enabled significant success and an increase in the number of applications supplied to customers in various plant engineering and construction sectors. manufacturing industry.

Do you need to make a mechanical transmission of motion?

Our engineering department is at your disposal for the design and manufacture of power transmission couplings.